When transitioning to PVC or CPVC piping, it’s best to do so at an elbow, tee or coupling with a female connection. It’s a good idea to replace as many as you can when remodeling or upgrading your system. Galvanized pipes corrode as they age, restricting water flow and leaving your plumbing vulnerable to leaky, broken pipes. Your bluefrog Plumbing + Drain plumber is familiar with local codes and can provide the best options for your home. Some plumbing codes require CPVC for all indoor pipes. However, hot water comes through your indoor pipes under pressure, so your plumber will use CPVC or metal pipes to replace older galvanized pipes indoors. White PVC pipes are ideal for outdoor plumbing because they are easy to find and replace. However, other materials, such as PVC and plastic, have withstood the test of time better. Galvanized metal pipes were once the material of choice for residential plumbing systems. Water flows more easily through PVC, which may prevent frequent clogs. Our plumbers often recommend it for homeowners upgrading their plumbing. The durable material is far more flexible than traditional metal pipes such as steel or copper. PVC is lightweight and has a high tolerance for chemicals used to clean drains and clogs. They are useful for vent piping, drainpipes and exterior drainage. Many homes and businesses contain PVC pipes. Learn more about PVC and Metal Piping and why it’s sometimes advantageous to mix these two types of pipes.

We know that you want to know what’s going on when it comes to the health and welfare of your home and family. At bluefrog Plumbing + Drain, we fully explain the changes we make, including the materials and equipment used.

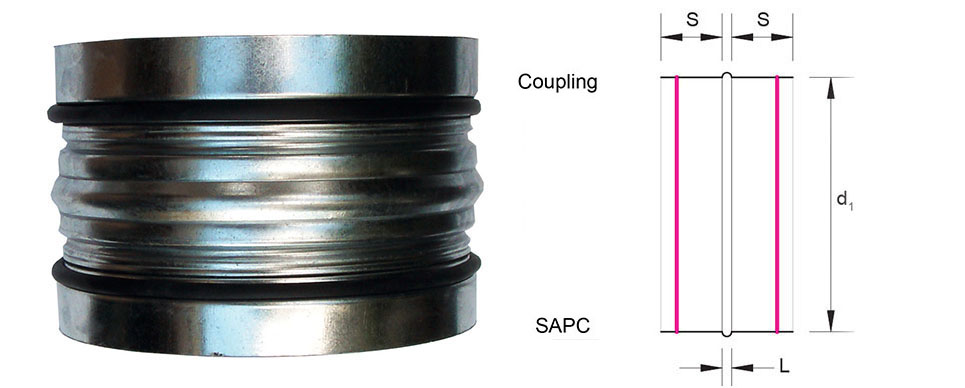

Splice cast iron pipe with compression coupling professional#

However, it’s good to understand how, why and when a plumbing professional might use two different materials when working in your home. Splices shall not be installed in areas where the harness is designed to flex.Working with different materials is best left to your plumber. Replacement conductors shall be of the same voltage and current rating as the original conductor. Western Union splices are used for solid conductors.Ĭable ties/lacing shall not be installed across the splice/solder sleeve body, unless sufficient protection is provided to prevent compression damage to the termination and/or to the insulation of adjacent conductors. Tubing is tightly shrunk, with proper strain relief, overlap and no exposed conductive surfaces. The termination is fully wetted, smooth and shiny. Tubing is tightly shrunk with proper strain relief, overlap and no exposed conductive surfaces. Tubing is tightly shrunk with proper strain relief. The termionation is fully wetted, smooth and shiny. Conductor(s) exhibit proper bend radius and strain relief. Overlaps meet minimum electrical spacing, while providing strain relief. Indents are symmetrical and centered on the crimp barrel. The contact has been deformed only by tool indenters. Final assembly profile shall not impact form, fit or function.Ĭable ties/lacing shall be installed at both ends of a splice or solder sleeve, but placement shall not violate stress relief requirements. The location of splices shall be staggered to minimize the increase in profile to the harness. The splice exhibits a smooth profile, proper strain relief, and is located in an area of the harness not subjected to flexure. See Section 4.01 "Cable and Harness, General Requirements", and Section 6.01 "Through-Hole Soldering, General Requirements", for common accept/reject criteria. CABLE AND HARNESS SPLICES CABLE AND HARNESSĪ splice is the joining of two or more conductors together in a manner that results in a permanent electrical termination and mechanical bond, and may be completed by either crimp or solder process.

0 kommentar(er)

0 kommentar(er)